| View previous topic :: View next topic |

| Author |

Message |

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Sun Jun 14, 2015 10:57 am Post subject: Made a Boost Controler today.. Posted: Sun Jun 14, 2015 10:57 am Post subject: Made a Boost Controler today.. |

|

|

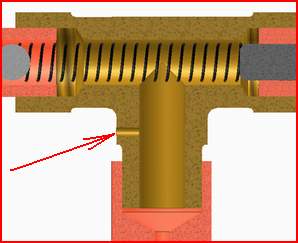

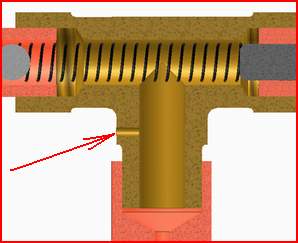

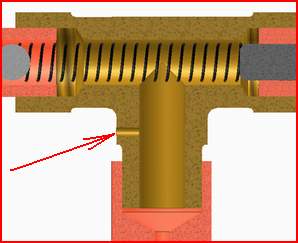

I think...

I know I still need a nut to lock my adjustment bolt, I couldn't find one around for the fine thread so I'll have to grab one from the hardware store.. The bolt hits the spring just about 3/16 down so it should leave me plenty of adjustment.

What the bolt goes into is the base of an old pressure gauge, I cut the gauge off of it, drilled its 1/8th inch hole out just big enough for my spring.. Then I found this fine thread bolt just a smidge bigger than my hole, happened to have the correct tap for it (I have a few  ), and tapped it.. ), and tapped it..

Then the 1/4" double male that the ball sits on, I chamfered the hole in it 45 degrees with a chamfering reamer, then set my ball in the taper and whacked it a bunch of times with a small hammer turning the ball every time for the ball to make its own perfect little seat in there.. I first tried this with pipe instead but the hole was too big for my ball and this is the biggest ball I have that fits in the brass T..

It is BIG, not going to have air volume trouble with this one like the boost T's..

The MBC inlet is going to couple to the threaded stud sticking out of the charge pipe with a hose and 2 clamps..

The outlet as you can see has an adaptor to make it bigger that I turned most of the outside threads off of on the drill press with a file. It's too much work to indicate the 4 jaw chuck on the lathe to center for such a small job. Backspace: better not get carried away yapping about that..

The MBC outlet is going to couple from the MBC with a hose on its big adaptor, over and passed the hex of the wastegate line, and clamp over the crimp fitting of the wastegate line all the way over the hex.. So I don't have to hurt anything or spend ridiculous money on some metric adaptors..

Does a MBC need a tiny leak on the wastegate side so it does not act as a check valve and hold pressure in the wastegate and line?

How does that work out? It seems it would open letting pressure to the WG and then that pressure would be trapped by the ball like a one way check valve and that doesn't sound good..

What do you guys think? Does it look good or should I chuck it for some chinese ricer MBC with tiny ports?

This cost me $0.00 BTW + a $0.10 nut I need to pick to lock the adjustment bolt..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

jason c

Joined: 13 Jan 2014

Posts: 1018

Location: Nwi

|

Posted: Sun Jun 14, 2015 12:36 pm Post subject: Posted: Sun Jun 14, 2015 12:36 pm Post subject: |

|

|

A boost controller bleeds off pressure in the line going to the wastegate to keep the wastegate from opening when manifold & thus line pressure reaches the wastegate springs threshold.

What you have made is a homemade lindsey boost enhancer. The boost enhancer works (or suppose to work) by holding back all pressure to the wastegate until a certain set pressure is met. This pressure overcomes the spring pressure and then is sent to the wastegate. The idea is to hold back pressure from reaching the wastegate until full manifold pressure is reached to prevent wastegate creep.

While it does work, the enhancer still creeps pressure itself.

It works on the 951 but the system is different than the 931. Study the 951 cycling valve.

What you have could work as a boost enhancer but you would need a wat to bleed off pressure so the wastegate doesn't stay open. A MBC setup downwind would accomplish that because it doesn't contain a check valve. You would have to adjust boost with the MBC & use the enhancer as an enhancer. It will take quite a bit of fiddling to get it set right.

You might be able to set it close with an air compressor but it won't be accurate. Both volume & pressure affect adjustment. Pressure is easy, getting the same volume is tough.

I spent alot of time doing test on the lbe & wastegate using compressed air. |

|

| Back to top |

|

|

leadfoot

Joined: 11 Dec 2002

Posts: 2222

Location: gOLD cOAST Australia

|

Posted: Sun Jun 14, 2015 1:17 pm Post subject: Posted: Sun Jun 14, 2015 1:17 pm Post subject: |

|

|

there has been alot of discussion on this...

basically with our dual port wastegates the safest way to increase boost is to apply additional pressure to the TOP port (which is normally vented to air via the mushroom breather)

IF the system fails for what ever reason it returns to factory specs and you don't overboost your engine, hopefully the fuel cut out saves it first though going the route you're thinking of....

So... buy a cheap air regulator off ebay for like $5, two brass hose fittings and a hose barb for the top port of the wastegate and connect it all in series to manifold boost pressure....

adjust reg to allow boost to keep the wastegate closed longer and provide additional boost to the engine....

about $10 in parts... and also allows for very precise configuration

run the lines into the cab and you have full adjustment any time you want...

_________________

1981 ROW 924 Turbo -

carbon fiber GT mish mash

LS1 conversion in progress... |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Sun Jun 14, 2015 1:49 pm Post subject: Posted: Sun Jun 14, 2015 1:49 pm Post subject: |

|

|

I realize the WG top port method is superior in all ways, but frankly I'm a bit burnt out on hard to reach bolts under the car right now, and if one of those J pipe - manifold bolts break I'm really screwed..

I've run across http://speedracer90.tripod.com/mbc/ that recommends a 1/32 hole to atmo on the WG side of such a boost device to bleed off any remaining pressure without interfearing with the signal pressure opening the WG.

Maybe I should have mentioned that I'm going for single port boost control vs dual port, I think those J pipe bolts are the scariest on the whole car..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

jason c

Joined: 13 Jan 2014

Posts: 1018

Location: Nwi

|

Posted: Sun Jun 14, 2015 2:25 pm Post subject: Posted: Sun Jun 14, 2015 2:25 pm Post subject: |

|

|

| leadfoot wrote: | there has been alot of discussion on this...

basically with our dual port wastegates the safest way to increase boost is to apply additional pressure to the TOP port (which is normally vented to air via the mushroom breather)

IF the system fails for what ever reason it returns to factory specs and you don't overboost your engine, hopefully the fuel cut out saves it first though going the route you're thinking of....

So... buy a cheap air regulator off ebay for like $5, two brass hose fittings and a hose barb for the top port of the wastegate and connect it all in series to manifold boost pressure....

adjust reg to allow boost to keep the wastegate closed longer and provide additional boost to the engine....

about $10 in parts... and also allows for very precise configuration

run the lines into the cab and you have full adjustment any time you want... |

Unless there's a leak in the side line to the wastegate, then the pressure to the top extrapolates that leaks effect.

| Fasteddie313 wrote: | I realize the WG top port method is superior in all ways, but frankly I'm a bit burnt out on hard to reach bolts under the car right now, and if one of those J pipe - manifold bolts break I'm really screwed..

I've run across http://speedracer90.tripod.com/mbc/ that recommends a 1/32 hole to atmo on the WG side of such a boost device to bleed off any remaining pressure without interfearing with the signal pressure opening the WG.

Maybe I should have mentioned that I'm going for single port boost control vs dual port, I think those J pipe bolts are the scariest on the whole car.. |

You'll be dealing with those bolts when you smoke the motor.

Any hole in the line that bleeds off pressure interferes with the wastegate, thats what its for.

Both designs have inherent risk, neither is significantly safer than the other. Both rely on secure lines.

The risk is in your boost enhancer holding pressure & causing an overboost. |

|

| Back to top |

|

|

Carrera RSR

Joined: 08 Jan 2010

Posts: 2309

Location: Somerset, UK

|

Posted: Mon Jun 15, 2015 3:45 am Post subject: Posted: Mon Jun 15, 2015 3:45 am Post subject: |

|

|

https://www.youtube.com/watch?v=LZWaSIQcuuo

_________________

1980 931 - forged pistons, Piper cam, K27/26 3257 6.10 hybrid turbo, 951 FMIC, custom intake, Mittelmotor dizzy & cam pulley, H&S exhaust, GAZ Gold, Fuch'ed, Quaife

Now www.924board.org/viewtopic.php?t=34690

Then www.924board.org/viewtopic.php?t=31252 |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Mon Jun 15, 2015 4:46 am Post subject: Posted: Mon Jun 15, 2015 4:46 am Post subject: |

|

|

Ok I've come to the conclusion that in a good boost controller, the bolt adjusting the ball spring adjusts the "boost enhancer" like the lindsay product.. They also rely on this part for the "restriction" so the bleed of actually works.. Boost controllers have these but many are not adjustable..

And then you need a needle valve to adjustably bleed off air on the WG side of the enhancer/restrictor device, this is how most boost controllers are adjusted..

They adjust boost with bleed valve and a fixed ball spring tension, VS adjusting the ball spring tension with a fixed bleed..

So instead of drilling a small hole to bleed what I need is a needle valve bleed to atmo after the enhancer/restrictor part.. So I made HALF a MBC with adjustable enhancement/restriction..

But I've hit a huge road block..

Long story short, first I sucked on the WG line, no vacuum..

Then I attached my air compressor to the WG line, it actuates just fine with a squeaky spring but air is bleeding off..

I set the air pressure low to the WG and crawl under the car, sounds like the air is going out the WG dump pipe, diaphragm fubared..

This really sucks and is a bit disheartening, I don't want to even run it standard with a leaking WG correct? Thats a whole lot more work and $$ before I can run it again after building another hybrid turbo and fabbing a whole FMIC that is a lot of work, $$, and downtime in between runs..

If anything breaks removing the WG this car will not run for a very long time, it will probably shoot the whole summer

I am going to go spray the crap out of those J pipe bolts... Any advice on how to remove them safely? I can feel them staring me down...

Nevermind, they came right off..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Mon Jun 15, 2015 8:13 am Post subject: Posted: Mon Jun 15, 2015 8:13 am Post subject: |

|

|

What a terrible job... 2 broken WG studs...

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

leadfoot

Joined: 11 Dec 2002

Posts: 2222

Location: gOLD cOAST Australia

|

Posted: Mon Jun 15, 2015 12:48 pm Post subject: Posted: Mon Jun 15, 2015 12:48 pm Post subject: |

|

|

It's actually far easier to remove the whole engine with exhaust down pipe connected than to stuff around removing exhaust components bit by bit...

drain remove rad

remove cross member and steering together

undo fuel feed/return - leave dissy connected (with mount removed)

undo electrical, starter/alt and loom connections multipin,earth straps

remove boost/vac line to booster/ecu/wur etc

remove clutch slave

break exhaust at bottom of downpipe and remove hanger/wastegate bracket support...

undo engine mounts

undo 4 bolts at torque tube

remove engine

basics, but essential done in about 3/4 hours

I use either a spare tyre or engine stand to work on... complete access to engine.... no busted knuckles

once you've done it once or twice it becomes quicker...

_________________

1981 ROW 924 Turbo -

carbon fiber GT mish mash

LS1 conversion in progress... |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Mon Jun 15, 2015 1:37 pm Post subject: Posted: Mon Jun 15, 2015 1:37 pm Post subject: |

|

|

I believe you but I don't have a hoist

My WG - chassis bracket was broke right in half you believe that? I got one of its bolts out, and once I loosened the other, half the bracket swung down.. Going to have to replace that..

2 studs where the WG bolts to the J pipe broke, and I couldn't get one of the nuts off period so I did have to pull the whole exhaust to get theWG and J pipe off in one piece, I later was trying to spin the nut off on the bench with a chisel, it didn't budge a second until I chiseled it completely in half...

I have the WG sitting in a pan of straight pure WD40, the studs broke at the nut so there is the flange thickness left of them to grab, I hope I can get them out without too much effort tomorrow..

This is the best solution I have found so far..

http://www.patrickmotorsports.com/part/exhaust-wastegate-service-set-911-turbo-930-965/

$185 for diaphragm, studs, nuts, and gaskets..

Anyone know where to get just a diaphragm at a reasonable price?

An in cabin knob, on a flex shaft drive (like a table saw), to the top of the WG to adjust spring pressure would be insane..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Mon Jun 15, 2015 2:32 pm Post subject: Posted: Mon Jun 15, 2015 2:32 pm Post subject: |

|

|

[img] [/img] [/img]

I'd have to do some measuring to see how much room there is before the diaphragm piston would bottom out against the top in its full valve travel taking into account room for actual downward adjustment.. Eliminating the bearing would increase headroom..

Would this be a superior method of boost control VS MBC?

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Tue Jun 16, 2015 8:17 am Post subject: Posted: Tue Jun 16, 2015 8:17 am Post subject: |

|

|

there is only 1" of room between the bottom of the top and the top of the nut on the valve stem with the valve in the full UP position..

I am in the process of trying to get studs out of the holes in the valve housing, this really sucks a lot, I may have to take it to the machine shop..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

Rasta Monsta

Joined: 12 Jul 2006

Posts: 11723

Location: PacNW

|

Posted: Tue Jun 16, 2015 8:29 am Post subject: Posted: Tue Jun 16, 2015 8:29 am Post subject: |

|

|

Search for 930 diaphragm.

I did a write up on this job at one point...

_________________

Toofah King Bad

- WeiBe (1987 924S 2.5t) - 931 S3

|

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Tue Jun 16, 2015 8:43 am Post subject: Posted: Tue Jun 16, 2015 8:43 am Post subject: |

|

|

| Rasta Monsta wrote: | Search for 930 diaphragm.

I did a write up on this job at one point... |

Yes and thank you, I have been referencing it a lot, great job.. http://www.924board.org/viewtopic.php?t=34966&highlight=

I have chinese cam lock stud extractors as opposed to your better collet style stud extractors, mine did grip them plenty enough to break them off but putting one on an impact gun just really wore down the outside of the stud until it would no longer grab it, went through 3 tanks of air on a blue point 3/8 low volume impact trying this..

Eventually heating with the hottest torch I have the Knipex Cobras (badass) broke them off..

All 4 broken on the J pipe side and one on the exhaust side I haven't touched yet..

This is where I'm at..

Absolutely love this drill press, 1955 CMan with variable speed, 300#s, milling quill, etc.. $75 garage sale.. I just put the drill down in the hole and locked the quill for the pics..

Irwin Hanson easy outs rock, I'm going to try them after I can get/borrow a torch for heat..

I don't think the studs were especially hard steel, USA HSS drill bit went all the way through em like butter, long curly chips, set my depth stop to inserted stud length as not to drill into the cast, low speed, WD40, also trammed the chuck to the table right beforehand with a right angle and a very straight snap on phillips screwdriver.Also ground flat - center punched the broken stud ends the best I could by eye in the first place..

I don't fancy disassembling the WG any further, there is some small play in the valve stem but I believe it's serviceable..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

Rasta Monsta

Joined: 12 Jul 2006

Posts: 11723

Location: PacNW

|

Posted: Tue Jun 16, 2015 10:08 am Post subject: Posted: Tue Jun 16, 2015 10:08 am Post subject: |

|

|

Needs oxy-acetylene

_________________

Toofah King Bad

- WeiBe (1987 924S 2.5t) - 931 S3

|

|

| Back to top |

|

|

|