|

924Board.org

Discussion Forum of 924.org

|

| View previous topic :: View next topic |

| Author |

Message |

bureau13

Joined: 07 Sep 2017

Posts: 480

Location: South Florida

|

Posted: Thu Jun 20, 2019 12:33 am Post subject: Posted: Thu Jun 20, 2019 12:33 am Post subject: |

|

|

Do you not have the frequency valve at all? Or just no lambda control of it?

| Carrera RSR wrote: | | Glad we don't have this added complication on RoW cars.......and we get more power! |

_________________

-----------------------------------------

1982 931

1986.5 Silver 928S

2007 Hummer H3 (Daily Driver)

Past lives (I miss them all):

2004 RX-8 (Wrecked)

1993 RX-7 (Sold)

1987 RX-7 Turbo II (Sold)

1985 RX-7 GSL (Stolen) |

|

| Back to top |

|

|

TJC

Joined: 04 Apr 2010

Posts: 828

Location: Central-ish Arizona, USA

|

Posted: Thu Jun 20, 2019 1:26 am Post subject: Posted: Thu Jun 20, 2019 1:26 am Post subject: |

|

|

| Carrera RSR wrote: | | Glad we don't have this added complication on RoW cars.......and we get more power! |

Considering this, how difficult would it be to convert a US system to RoW?

Would it make things simpler and the way Porsche intended it to be in the first place in spite of the stupid regulations imposed on US cars?

_________________

'95 BMW 318i/5 ..."Pearl"

'87 Porsche 944 NA... "Liebchen"

'02 Porsche Boxster..."Sunbeam"

'04 BMW X3..."Xander"

Still on the Prowl!

www.ttrs1.com |

|

| Back to top |

|

|

924-76

Joined: 05 Jun 2006

Posts: 1475

Location: Ontario, Canada

|

Posted: Thu Jun 20, 2019 2:15 am Post subject: Posted: Thu Jun 20, 2019 2:15 am Post subject: |

|

|

Just unplug your O2 sensor and reset your idle A/F ratio with the fuel adjustment screw on the fuel metering head.

As mentioned above, by unplugging your O2, your system will go in safe more and over fuel which should put you in the low 10 A/F ration or lower. I did that over a year ago and never looked back.

_________________

1976 924 N/A ROW SOLD

1980 931S

1981 931 Part car RIP |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Thu Jun 20, 2019 11:28 am Post subject: Posted: Thu Jun 20, 2019 11:28 am Post subject: |

|

|

Some updates...

I spoke with the previous owner and asked about the lambda system...it is complete...with the O2 sensor connected there is a hesitation...he had unplugged the sensor and that cleared up the hesitation.

Tonight I put the car up on ramps and reconnected the O2 sensor. i immediately noticed the hesitation he mentioned, not sure what is going on there.

In any case, on boost in 2nd, 3rd and 4th gears, the AF meter quickly drops below 13 to 11.9, 12.1, 12.2., 12.3 as I was able to glance down. So that is an improvement over the 13s I was seeing previously. But 5th gear is a different story...going about 70mph and giving throttle (and building boost at around 3000rpms), the AF meter is in the high 13s and even 14s. Giving more throttle to build more boost and RPMs doesn't change the readings.

I wasn't able to drive the car too much but did not notice the original problem that started this thread...power dropping off in the higher RPMs. Will get a chance to drive more soon.

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Thu Jun 20, 2019 2:23 pm Post subject: Posted: Thu Jun 20, 2019 2:23 pm Post subject: |

|

|

Is/was the frequency valve buzzing before/after whatever you did with the fuel pump power jumped or engine running?

You made it sound like the lambda system was completely not working, as in no frequency valve action at all, and just plugging the O2 back in would not fix that..

Find a dwell meter to measure the duty cycle of the frequency valve at idle and you can tune your AFR screw to the correct duty cycle.. Proper way to set your base AFR..

They should be cheap, they are old tech..

If you want to try to tune the AFR screw to your AFR gauge you will find a range of adjustment in the AFR screw that will cross back and forth across 14.7..

You want to turn the AFR screw to the right untill it stops crossing back and forth across 14.7 and then back left until it just starts crossing 14.7 again so you are on the rich side of the lambda's ability..

Go left untill it is lean at idle, then back right and you will find an area where it goes back and forth across 14.7, then if you keep going right it will stop crossing and just stay rich, turn it back a bit to where it crosses 14.7 again but bias toward righty tighty in that area where it will cross 14.7..

With a dwell meter you want to set it to where it crosses about 45% duty cycle. Set it to where it will swing from like 42% to 48% back and forth..

With a narrrowband sensor the computer can only really tell when it crosses 14.7 but never what the AFR actually is, so it makes it cross 14.7 back and forth as good as possible..

As soon as it gets lean it turns around and increases the duty cycle to richen untill it crosses 14.7 and then it turns around and decreases the duty cycle to lean until it crosses 14.7 again, back and forth staying near 14.7..

Each swing takes 1 or 2 seconds, smooth back and forth..

If your AFR screw is in the range where the lambda system can cross 14.7 (tend toward the rich side) the the entire AFR map's base setting is about right..

Then if you have no vacuum leaks it will run right, if your system pressure and warm/cold/boost control pressures and residual pressure are in spec

Oh and ignition timing, cam timing, compression, fuel pump pressure..

In all reality you will NEVER KNOW if it is actually right unless you do a CIS test as outlined in the hanyes manual..

If the CIS pressure test is RIGHT, injector test as outlined in the haynes manual is RIGHT, fuel pump flow test in haynes is RIGHT, then it's RIGHT.. But you will never KNOW for sure otherwise..

How to connect & operate the Hoffman CIS Test Kit

If you are serious about wanting to make your car right do the cis pressure tests and injector test, in which you will learn a lot about CIS and how CIS works..

My lambda system always just worked fine so I never really had to troubleshoot it other than the TB switches being out of adjustment and tuning it so I don't know a lot about how to fix it from scratch to be honest, and now my car doesn't have the lambda system anymore at all but rather a slightly newer thing that tunes completely off of lower chamber pressure, the next evolution of "lambda", and has no WUR stuff..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Fri Jun 21, 2019 12:29 am Post subject: Posted: Fri Jun 21, 2019 12:29 am Post subject: |

|

|

| Fasteddie313 wrote: | | Is/was the frequency valve buzzing before/after whatever you did with the fuel pump power jumped or engine running? |

I'm not sure.

| Quote: |

You made it sound like the lambda system was completely not working, as in no frequency valve action at all, and just plugging the O2 back in would not fix that. |

That was a misunderstanding on my part. When I bought the car I thought I heard that the system was disconnected. Turns out that only the O2 sensor was disconnected. Again, not sure about the frequency valve, will need get under the hood to listen for it. I'm afraid I don't know what I don't know...still on the learning curve but busy studying.

| Quote: |

Find a dwell meter to measure the duty cycle of the frequency valve at idle and you can tune your AFR screw to the correct duty cycle.. Proper way to set your base AFR..

They should be cheap, they are old tech.. |

Will pick one up.

| Quote: |

If you want to try to tune the AFR screw to your AFR gauge you will find a range of adjustment in the AFR screw that will cross back and forth across 14.7..

You want to turn the AFR screw to the right untill it stops crossing back and forth across 14.7 and then back left until it just starts crossing 14.7 again so you are on the rich side of the lambda's ability..

Go left untill it is lean at idle, then back right and you will find an area where it goes back and forth across 14.7, then if you keep going right it will stop crossing and just stay rich, turn it back a bit to where it crosses 14.7 again but bias toward righty tighty in that area where it will cross 14.7..

With a dwell meter you want to set it to where it crosses about 45% duty cycle. Set it to where it will swing from like 42% to 48% back and forth..

With a narrrowband sensor the computer can only really tell when it crosses 14.7 but never what the AFR actually is, so it makes it cross 14.7 back and forth as good as possible..

As soon as it gets lean it turns around and increases the duty cycle to richen untill it crosses 14.7 and then it turns around and decreases the duty cycle to lean until it crosses 14.7 again, back and forth staying near 14.7..

Each swing takes 1 or 2 seconds, smooth back and forth..

If your AFR screw is in the range where the lambda system can cross 14.7 (tend toward the rich side) the the entire AFR map's base setting is about right.. |

Thanks for this information.

| Quote: |

Then if you have no vacuum leaks it will run right, if your system pressure and warm/cold/boost control pressures and residual pressure are in spec

Oh and ignition timing, cam timing, compression, fuel pump pressure..

In all reality you will NEVER KNOW if it is actually right unless you do a CIS test as outlined in the hanyes manual..

If the CIS pressure test is RIGHT, injector test as outlined in the haynes manual is RIGHT, fuel pump flow test in haynes is RIGHT, then it's RIGHT.. But you will never KNOW for sure otherwise..

How to connect & operate the Hoffman CIS Test Kit

|

Haven't seen that many variables since calculus in college. But point taken.

| Quote: |

If you are serious about wanting to make your car right do the cis pressure tests and injector test, in which you will learn a lot about CIS and how CIS works.. |

The seller told me that'll I'll need a CIS pressure tester....

I found some links on Rennlist...how about this one:

https://www.amazon.com/Tool-Aid-33865-K-Jetronic-Injection/dp/B0002SR5NU/ref=sr_1_6?ie=UTF8&qid=1401305041&sr=8-6&keywords=cis+testing+kit#customerReviews

| Quote: |

My lambda system always just worked fine so I never really had to troubleshoot it other than the TB switches being out of adjustment and tuning it so I don't know a lot about how to fix it from scratch to be honest, and now my car doesn't have the lambda system anymore at all but rather a slightly newer thing that tunes completely off of lower chamber pressure, the next evolution of "lambda", and has no WUR stuff.. |

Hopefully after checking the items mentioned above I can get mine sorted out.

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Fri Jun 21, 2019 4:58 am Post subject: Posted: Fri Jun 21, 2019 4:58 am Post subject: |

|

|

| chuck21401 wrote: | Again, not sure about the frequency valve, will need get under the hood to listen for it. I'm afraid I don't know what I don't know...still on the learning curve but busy studying.

|

Jump pins 30-87 on your fuel pump relay and it should kick your fuelpump on and your lambda system, they are on the same power circuit..

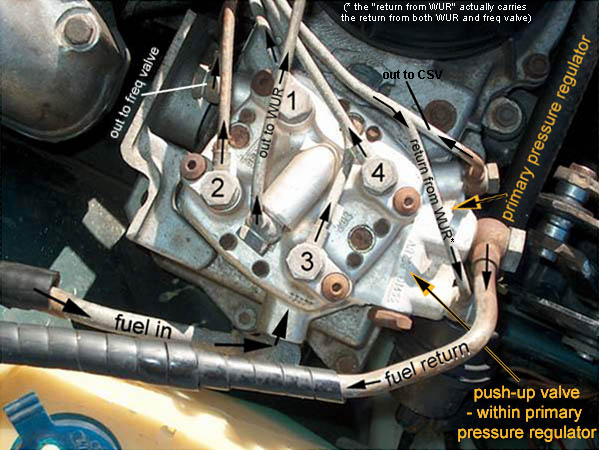

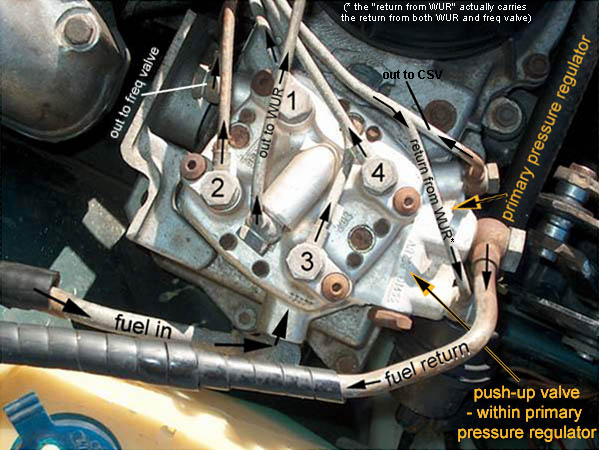

Their should be a thing buzzing under your TB.. That is the frequency valve.. Or follow the "out to freq valve" line to find it..

And while idling just grab it and feel if it is vibrating..

It'll work..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Tue Jun 25, 2019 3:51 am Post subject: Posted: Tue Jun 25, 2019 3:51 am Post subject: |

|

|

| Fasteddie313 wrote: | Jump pins 30-87 on your fuel pump relay and it should kick your fuelpump on and your lambda system, they are on the same power circuit..

Their should be a thing buzzing under your TB.. That is the frequency valve.. Or follow the "out to freq valve" line to find it..

And while idling just grab it and feel if it is vibrating.. |

I'm pretty certain that the frequency valve is running. The line was vibrating at the frequency valve.

Thanks. The pressure tester should arrive this week and I received the multi-tester with dwell over the weekend.

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Fri Jun 28, 2019 12:55 am Post subject: Returning to the original problem Posted: Fri Jun 28, 2019 12:55 am Post subject: Returning to the original problem |

|

|

It appears that reconnecting the O2 sensor wire has helped with the A/F ratios. Under boost I'm seeing low 12s when I hit in 2, 3 and 4. First gear is too short and I have a tough time getting into 2nd gear so I don't push to hard in first. Oddly the A/F ratios are still in 13/14s in 5th gear under boost...why would that be the case? Another mystery. Above 60mph when you give it throttle the boost builds quickly but the A/F ratio doesn't drop much, so I'm avoiding pushing it in 5th.

I was hoping that addressing the A/F ratio would help with the original topic of the thread which is occasionally loosing power at high RPMs. I don't think I'm losing boost and air/fuel ratio seems better but I quickly noticed that the problem remained. So I started searching threads related to ignition and spark plugs. Long story short, I decided to pull a plug to take a look at and check the gap. Here are pics from two different angles:

Any observations from the pictures?

The plugs are NGK BPR7ES

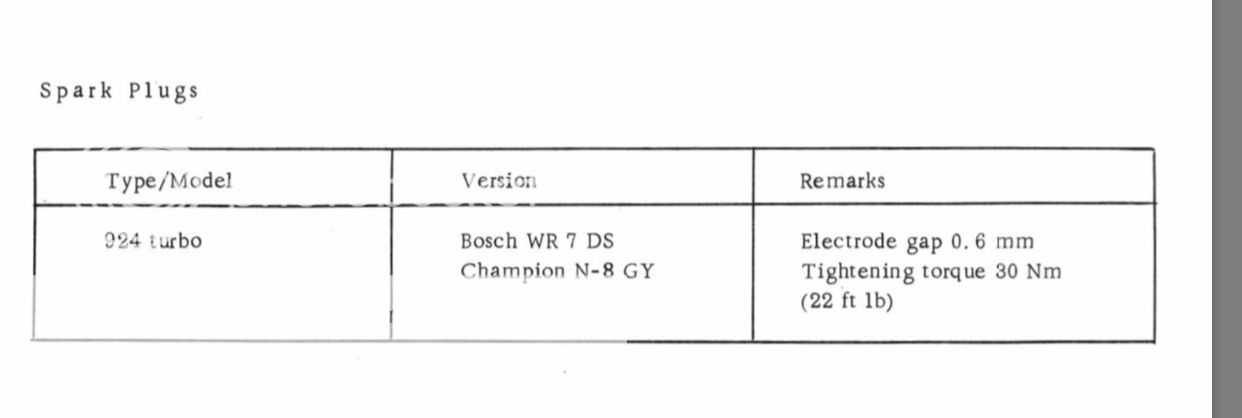

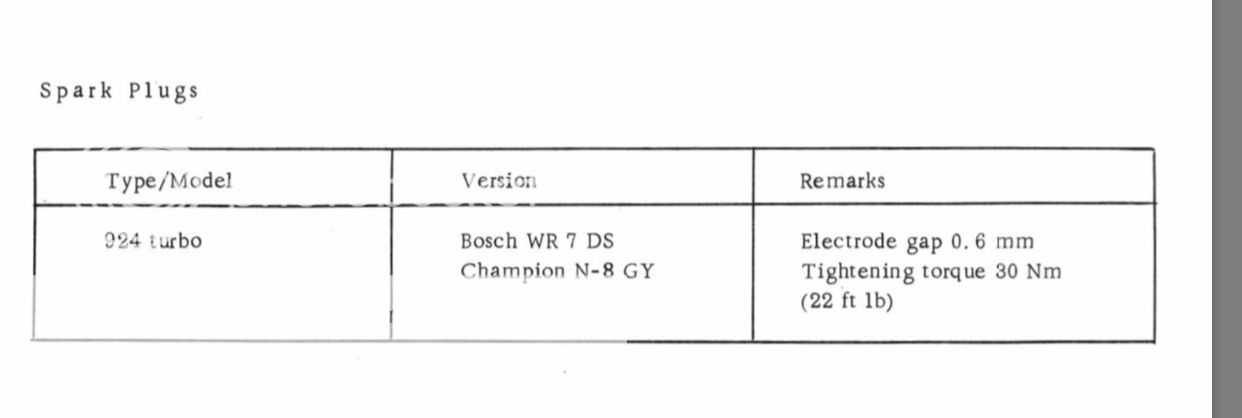

When I checked the gap with a feeler gauge the gap was .8mm. I read through the forum and found others stating the gap should be .7mm or .7mm +/- 1 (so .6mm to .8mm?) I did more searching and found a PDF titled "Porsche 924 turbo Assembly and adjusting instructions" and it included this table:

Seeing that number cited made me wonder if the plug gap was too wide. Maybe my ignition system isn't strong enough to jump the gap under boost? So then I decided to check the other plugs...which turns out to be a bit more involved. I decided to pull the charge tube to make it a lot easier to get to at least the plug under it.

So here is a surprise...some oil in the throttle body. I ran some searches and apparently that can be caused by a number of concerns. But for now I pressed on with the spark plugs.

The other plugs were gapped the same. Did more searches regarding plugs and found that someone mentioned that B8EGV plugs worked well. I checked a local Advance Auto Parts and they had a set in stock for $6 each. So I bought the set and checked the gap.... .6mm. Interesting. OK, so the story is getting long...I tried out the new plugs around found the following:

1. The loss of power at high rpms is not happening (maybe just a coincidence? not sure)

2. Previously boost was 13-14psi on the gauge and now is more like 15psi plus. Yikes.

How is this happening? 1 bar boost spring in the wastegate? Is the wastegate control line leaking? Connections on both ends appear to be tight...could the rubber line have a pin hole?

Here is a pic of the spring as the wastegate was being rebuilt...any way to tell anything from the picture?

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler

Last edited by chuck21401 on Fri Jun 28, 2019 1:18 am; edited 3 times in total |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Fri Jun 28, 2019 1:05 am Post subject: Setting A/F with dwell meeting Posted: Fri Jun 28, 2019 1:05 am Post subject: Setting A/F with dwell meeting |

|

|

The dwell meter arrived but didn't get a chance to try it out until Tuesday.

Here is an initial reading...

But really it jumped around quite a bit...so here is a 14 second video:

https://youtu.be/4IEnYe3s5Fo

I didn't mess around with 3mm mixture screw...seems like these readings are about right? Maybe 1/4 turn richer?

The CIS system tester also arrived but I haven't tried that out yet.

I think my main concern right now is too much boost without an intercooler.

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler

Last edited by chuck21401 on Fri Jun 28, 2019 1:19 am; edited 1 time in total |

|

| Back to top |

|

|

Carrera RSR

Joined: 08 Jan 2010

Posts: 2309

Location: Somerset, UK

|

Posted: Fri Jun 28, 2019 1:15 am Post subject: Posted: Fri Jun 28, 2019 1:15 am Post subject: |

|

|

Without any thermal management, 13/14AFR and 1.0bar boost, you are going to see detonation on your motor sooner than later.

Your intake temps on hard acceleration will be well over 100deg at 1.0 bar. You need to be in 10/11's AFR without an IC and high 11 to mid 12's with an IC managing the intake temps. You've now opened pandoras box knowing the data, so if the plugs are running better or more efficiently without any misfiring or losing power, you have now pulled the pin on the grenade........

Just because you can't hear the det from the cabin does not mean its not there. At best you'll blow the head gasket. At worse you'll hole the piston.

As for the oil, it's expected. Oil vapour from the crankcase is dragged through the intake via the Purolater.

_________________

1980 931 - forged pistons, Piper cam, K27/26 3257 6.10 hybrid turbo, 951 FMIC, custom intake, Mittelmotor dizzy & cam pulley, H&S exhaust, GAZ Gold, Fuch'ed, Quaife

Now www.924board.org/viewtopic.php?t=34690

Then www.924board.org/viewtopic.php?t=31252 |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Fri Jun 28, 2019 1:25 am Post subject: Posted: Fri Jun 28, 2019 1:25 am Post subject: |

|

|

| Carrera RSR wrote: | Without any thermal management, 13/14AFR and 1.0bar boost, you are going to see detonation on your motor sooner than later.

Your intake temps on hard acceleration will be well over 100deg at 1.0 bar. You need to be in 10/11's AFR without an IC and high 11 to mid 12's with an IC managing the intake temps. You've now opened pandoras box knowing the data, so if the plugs are running better or more efficiently without any misfiring or losing power, you have now pulled the pin on the grenade........

Just because you can't hear the det from the cabin does not mean its not there. At best you'll blow the head gasket. At worse you'll hole the piston.

As for the oil, it's expected. Oil vapour from the crankcase is dragged through the intake via the Purolater. |

Understood. Definitely don't want the grenade to go off. She's parked for now.

So what's the best was to figure out what is going on with the boost...and turn it down? Crack open the wastegate to see what spring is in there? Verify that the the boost control line isn't leaking? What are the other variables?

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler |

|

| Back to top |

|

|

Carrera RSR

Joined: 08 Jan 2010

Posts: 2309

Location: Somerset, UK

|

Posted: Fri Jun 28, 2019 1:38 am Post subject: Posted: Fri Jun 28, 2019 1:38 am Post subject: |

|

|

Some folks think putting in a 930 1.0bar WG spring is right for increased power. Its hard to check springs as they tend not to be marked. No idea if anyone tested springs anywhere? Downside to increased WG spring rate is you cannot turn down the boost. Its also a serious PITA to pull the WG off the exhaust to find out its the right spring.......but you may need to search and read a few more posts on how to tell what you have. You should be seeing 0.5-0.6bar on a stock US spring.

OR

Install some thermal management and leave the WG alone. Either meth injection and/or an IC. Anyone got a spare charge cooler that Dan was selling on his garage? Maybe drop him a line and see if he is able and willing to sell another

_________________

1980 931 - forged pistons, Piper cam, K27/26 3257 6.10 hybrid turbo, 951 FMIC, custom intake, Mittelmotor dizzy & cam pulley, H&S exhaust, GAZ Gold, Fuch'ed, Quaife

Now www.924board.org/viewtopic.php?t=34690

Then www.924board.org/viewtopic.php?t=31252 |

|

| Back to top |

|

|

chuck21401

Joined: 20 Feb 2005

Posts: 526

Location: Annapolis, MD

|

Posted: Fri Jun 28, 2019 2:27 am Post subject: Posted: Fri Jun 28, 2019 2:27 am Post subject: |

|

|

Is there a third option...run two lines to the wastegate + manual boost controller? I didn't follow everything in the threads that I found, but it appears there is a closed port that can be used to essentially create a dual port wastegate...would that provide the ability to turn down the boost?

_________________

1981 Porsche 931 w/S1 engine & g31 transmission. Water-cooled intercooler |

|

| Back to top |

|

|

Fasteddie313

Joined: 29 Sep 2013

Posts: 2596

Location: MI

|

Posted: Fri Jun 28, 2019 2:28 am Post subject: Posted: Fri Jun 28, 2019 2:28 am Post subject: |

|

|

That dwell reading looks perfect actually, for a digital gauge.. With an analog gauge with a needle you can actually watch its movement rather than seeing it just jump around but that is just about the right numbers you are looking for..

Does the dwell meter have different scales for a 4cyl and 6 cyl? Make sure it is on the 4cyl scale if it does.. Or maybe you are reading straight duty cycle with your meter and not "dwell" which would also be correct..

Ha ok so I looked at your meter setting and it is set correctly so never mind that..

Are you using the test port by the brake booster to measure it or are you hooking it right up to the frequency valve?

If you don't know about the test port is a 3 wire pigtail up by your brake booster area and the black wire gives a port to measure the freq duty..

Make sure your TB is closing the idle switch when the TB closes and closing the WOT switch when it's WOT..

Looks like your lambda system is working fine..

Your allen AFR screw is actually perfect where it is at but speaking of that screw, you do have the hole over the screw plugged with something right?

The hole to access the screw needs to be plugged/capped to be in correct operating condition..

| chuck21401 wrote: | | Is there a third option...run two lines to the wastegate + manual boost controller? I didn't follow everything in the threads that I found, but it appears there is a closed port that can be used to essentially create a dual port wastegate...would that provide the ability to turn down the boost? |

No, you can only use a boost controller to tun UP the boost.. The lowest you can go with a boost controller is what the WG spring will give you.. Unfortunately..

Fortunately you can limit the boost manually with the throttle pedal. When boost comes on just back off the throttle pedal a bit and run where the boost gauge reads 6-8 psi..

_________________

80 Turbo - Slightly Modified |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|